BOENNIGHEIM (msc) Textile products made from synthetic fibres, finished fabrics or dyed materials release fibre fragments into the environment at every stage of their life cycle. With the new DIN SPEC 19296, Hohenstein has developed a standardised testing method to analyse how these fragments behave in soil under natural conditions. Until now, little was known about their environmental behaviour or potential ecological effects once released.

Holistic testing approach

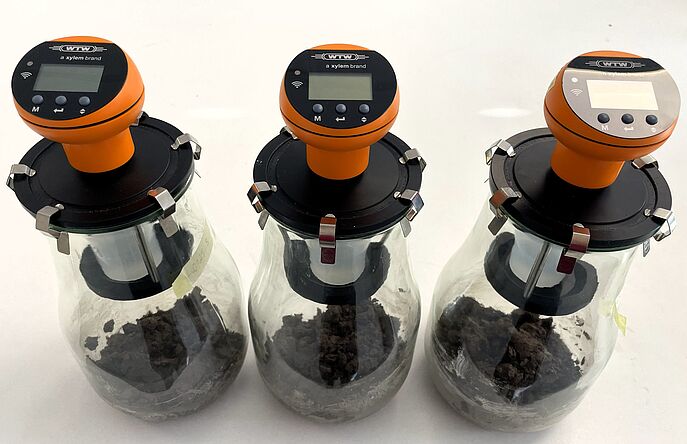

DIN SPEC 19296 focuses on textile products and the fragments released through use, abrasion or disposal. Tests are conducted in standardised soil under defined climatic conditions over a period of up to 180 days.

The method combines several parameters: a respirometer system measures the oxygen consumption of microorganisms during degradation, enabling the biodegradability of textile fragments to be quantified. Plant growth tests using cress seeds assess potential effects on vegetation after degradation. In addition, earthworms are used as sensitive bioindicators to evaluate possible toxic effects. Survival rates and changes in body mass indicate whether degraded fragments or residues have a negative impact on soil organisms.

This integrated approach not only determines whether materials are biodegradable, but also whether their fragments could harm plants or soil organisms.

Practical relevance and added value

“Textile fibres and fragments are released into the environment not only during washing, but also during everyday wear,” says Juliane Alberts, Project Manager at Hohenstein. “DIN SPEC 19296 allows us, for the first time, to assess under realistic conditions how different textile fragments behave in soil. It makes an invisible issue visible and supports the development of more sustainable textile products.”

The new DIN SPEC enables companies to compare textile products in terms of their potential environmental impact resulting from fibre release. It also provides a scientific basis for evaluating environmental claims such as “compostable”.

Jointly developed – publicly available

DIN SPEC 19296 was developed by Hohenstein in cooperation with industry partners and is publicly available. The results can help to better assess the actual environmental impacts of textile fiber loss, derive appropriate mitigation measures, and develop materials with lower environmentally harmful fiber shedding for the textile industry.

About Hohenstein

Hohenstein is a family-owned company with more than 80 years of experience in testing, certification and research. With roots in the textile sector, the Hohenstein testing portfolio now includes softlines, hardlines and medical products. Around the globe, approximately 1,500 employees work on testing and service offerings such as testing for harmful substances, performance testing or fit testing. Customers from all over the world receive everything from a single source: Hohenstein supports companies along the entire value chain, from the testing process and certification to the marketing of their products. The Hohenstein experts are experienced partners for more-sustainable materials, products and processes. As a founding member, Hohenstein is one of the most important laboratories for OEKO-TEX®, the world's leading certifier of textile and leather goods. For training and further education, the Hohenstein Academy provides online and classroom courses.